The Schaedla dry cleaner was in operation from 1907-1973. After the plant was closed down, the site was rezoned and a retirement home and residential buildings were constructed. After significantly elevated concentrations of CFCs were detected in the groundwater in the vicinity of the now overbuilt site, the city of Heidelberg commissioned MuP Umwelttechnik GmbH to investigate the hydrogeological situation in order to determine the extent of the groundwater contamination.

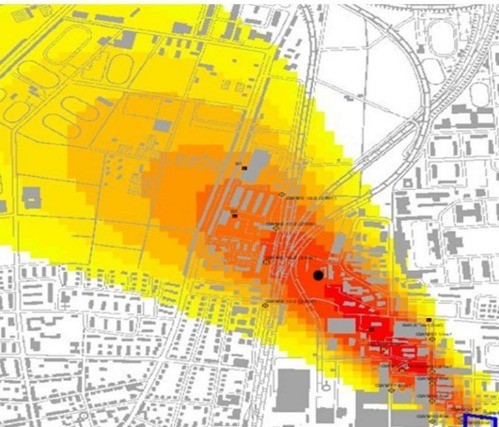

Based on the analysis results, the centre of the damage could be determined. The concentrations of CFCs here were up to 19,000 mg/m³. Based on the results of the detailed investigation by MuP Umwelttechnik GmbH, two soil air purification plants were constructed and put into operation. The step-by-step investigation of the pollutant plume and a numerical groundwater modelling illustrated the transport path of the pollutant in the groundwater.

Within the framework of the project, the following services have been supervised and carried out to date:

- Detailed investigation

- Setting up wells to the base of the aquifer

- Carrying out pumping tests

- Assessment of the extent of the plume

- Estimation of the total pollutant input

- Remediation survey

- Representation and analysis in a Geographical Information System (GIS)

Groundwater remediation:

At the beginning of the groundwater remediation, 125 m³ of water was extracted every hour from the 13 remediation wells, cleaned via wet activated carbon and filtered back into the groundwater. MuP Umwelttechnik GmbH monitors the progress of the remediation by means of groundwater monitoring (regular sampling, key date measurements, chemical analyses), which is carried out at approx. 50 wells in the inflow, in the source of the damage, in the side stream and in the near and further downstream. As the plume extends over several groundwater levels, monitoring is carried out both at shallow wells up to a depth of approx. 10 m and at deep wells up to 50 m deep.

Soil air remediation:

At present, only one soil air purification system with two extraction levels is still in operation. With the help of a side-channel compressor, the extracted air is first passed through a water separator and then purified through activated carbon. Afterwards, the purified air is released into the environment.

#groundwaterremidiation #groundwatercontamination #groundwaterremediation #mupheidelberg #mupgroup #EngineeringforaBetterTomorrow